Reliable Sponge Pvt. Ltd. is the leading manufacturer of Steel in the city of Rourkela.

The company has served various industries & businesses across India including

some of the large private sector businesses & also public sector companies.

Over the years Reliable Sponge Pvt. Ltd. has earned trust & respect more than

the profits. We have successfully satisfied all our clients in various verticals.

Reliable Sponge Pvt. Ltd. has evolved as an enterprise to meet the demands in infrastructure segments

across pan-India. We have made our presence felt strongly in diversification.

We value our customers who have shown in there trust in our capabilities.

Sponge Iron Unit based at Bonai ,Dist- Sundargarh. Established in 2004 Installed capacity of 200 TPD Sponge Iron.

This is an ISO 9001:2008 certified Company. Unit is situated at industrial estate Kalunga, Rourkela. Our License from Thermex to use the “Thermex Quenching System and Technology M/S Heenings Dorfer Stahl Technology”. The most advanced and latest technology in our new generation, High-strength ribbed TMT Bar. Steel Athority of India Ltd. had appointed us since 2010, as an authorised conversion partner for TMT Bars and Structural Steels. We have around 500 satisfied dealers of our “RELIABLE” brand steel products in Odisha.

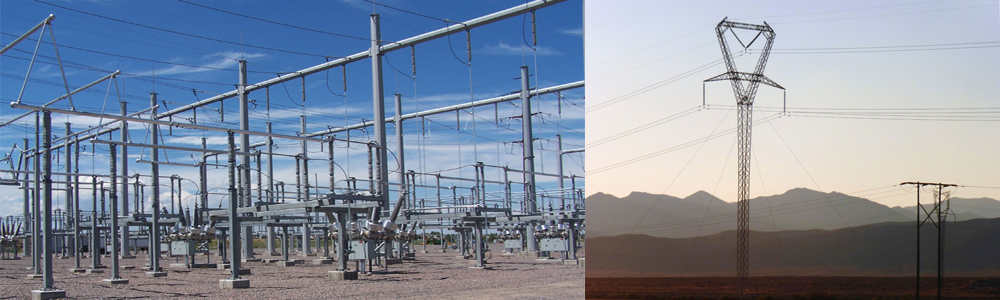

We provide today’s innovative applications and state-of-the-art technological developments in the fabrication and hot-dip galvanizing to prevent corrosion. Hot Dip Galvanizing is a method of giving long-term corrosion protection to steel by means of coating it with molten zinc. We are an experienced Engineering and manufacturing company handling jobs for Government, Public & Private sectors like PGCIL, BHEL, HSL, Indian Oil, CORE, NALCO, OPTCL, etc. Our application is in the field of Transmission Line Towers, Substation Structures, Railway Electrification OHE and TSS Structures, Solar Structures, etc.